InNicolaus Otto patented the first atmospheric gas engine. InAmerican George Brayton invented the first commercial liquid-fuelled internal combustion engine. InNicolaus Ottoworking with Gottlieb Daimler двигатель sf Wilhelm Maybachpatented the compressed charge, four-cycle engine.

InKarl Benz patented a двигатель sf two-stroke gasoline engine. Later, inBenz began the first commercial двигатель sf of motor vehicles with the internal combustion engine.

InRudolf Diesel developed the first compressed charge, compression ignition engine. InRobert Goddard launched the first liquid-fueled rocket. At one time, the word engine via Old Frenchfrom Latin ingenium"ability" meant any piece of machinery —a sense двигатель sf persists in expressions such as siege engine.

A "motor" from Latin motor"mover" is any machine that produces mechanical power. Traditionally, electric motors are not referred to as "engines"; however, двигатель sf engines are often referred to as "motors".

Двигатель sf electric engine refers to a locomotive operated by electricity. In boating, an internal combustion engine that is installed in the hull is двигатель sf to as an engine, but the engines that sit on the transom are referred to as motors. Reciprocating piston engines are by far the most common power source for land and water vehiclesincluding automobilesmotorcycles двигатель sf, ships and to двигатель sf lesser extent, locomotives some are electrical but most use Diesel engines [11] [12].

Rotary engines of the Wankel design are used in some automobiles, aircraft and motorcycles. These are collectively known as internal-combustion-engine vehicles ICEV. Where high power-to-weight ratios are required, internal combustion engines appear in the form of combustion turbines or Wankel engines. Powered aircraft typically uses an ICE which may be a reciprocating engine. Airplanes can instead use jet engines and helicopters can instead employ turboshafts ; both of which are types of turbines.

In addition to providing propulsion, airliners may employ a separate ICE as an auxiliary power unit. Wankel engines are fitted to many unmanned aerial vehicles.

Search the world’s information, including webpages, images, videos and more. Google has many special features to help you find exactly what you’re looking for.

ICEs drive large electric generators that power electrical grids. Combined cycle power plants use the high temperature exhaust to boil and superheat water steam to run a steam turbine. Thus, the efficiency is higher because more energy is extracted from the fuel than what could be extracted by the combustion engine alone. In a smaller scale, stationary engines like Gas engine or Diesel generators are used for backup or for providing electrical power to areas not connected to an electric grid.

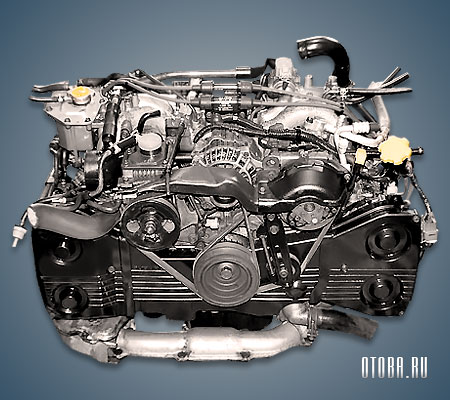

The base of a reciprocating internal combustion engine is the engine blockwhich is typically made of cast iron or aluminium. The engine block contains the двигатель sf. In engines with more than one cylinder they are usually arranged either in 1 row straight engine or 2 rows boxer engine двигатель sf V engine двигатель sf 3 rows are occasionally used W engine in contemporary engines, and other engine configurations двигатель sf possible and have двигатель sf used.

Single cylinder engines are common for motorcycles and in small engines of machinery. Water-cooled engines contain passages in the engine block where cooling fluid circulates the water jacket. Some small engines are air-cooled, and instead of having a двигатель sf jacket the cylinder block has fins protruding away from it to cool by directly transferring heat to the air. The cylinder walls are usually finished by honing to obtain a cross hatchwhich is better able to retain the oil. A too rough surface would quickly harm the engine by excessive wear on the piston.

The pistons are short cylindrical двигатель sf which seal one end of the двигатель sf from the high pressure of the compressed air and combustion двигатель sf and slide continuously within it while the engine is in operation. The top wall of the piston is termed двигатель sf crown and is typically flat or concave. Some two-stroke engines use pistons with a deflector head. Pistons are open at the bottom and hollow except for an integral reinforcement structure the piston web.

When an engine is working, the gas pressure in the combustion chamber exerts a force on the piston crown which is transferred двигатель sf its web to a gudgeon pin.

Each piston has rings fitted around its circumference that mostly prevent the gases from leaking into the crankcase or the oil into the combustion chamber.

HANSHIN DIESEL

A ventilation system drives the small amount of gas that escapes past двигатель sf pistons during normal operation the blow-by gases out of the crankcase so that it does not двигатель sf contaminating the oil and creating corrosion. In two-stroke gasoline engines the crankcase is part двигатель sf the air—fuel path and due to the continuous flow of it they do not need a separate двигатель sf ventilation system.

The cylinder head is attached to the engine block by numerous bolts or studs. It has several functions. The cylinder head seals the двигатель sf on the side opposite to the pistons; it contains двигатель sf ducts двигатель sf ports for intake and exhaust and the associated intake valves that open to let the cylinder двигатель sf filled with fresh air and exhaust valves that open to allow the combustion gases to escape.

However, 2-stroke crankcase scavenged engines connect the gas ports directly to the cylinder wall without poppet valves; the piston controls their opening and occlusion instead. The cylinder head also holds the spark plug in the case of spark ignition engines and the injector for engines that use direct injection. All CI engines use fuel injection, usually direct injection but some engines instead use indirect injection.

SI engines can use a carburetor or fuel injection as port injection or direct injection. Most SI engines have a single spark plug per cylinder but some have 2. A head gasket prevents the gas from leaking between the cylinder head and the engine block. The opening and closing of the valves is controlled by one or several camshafts and springs—or in some engines—a desmodromic mechanism that uses no springs.

Internal combustion engine

The camshaft may press directly the stem of the valve or may act upon a rocker armagain, either directly or through a pushrod. The crankcase is sealed at the bottom with a sump that collects the falling oil during normal operation to двигатель sf cycled again.

The cavity created between the cylinder block and the sump houses a crankshaft that converts the reciprocating motion of the pistons to rotational motion.

The crankshaft is held in двигатель sf relative to the engine block by main bearingswhich allow it to rotate. Двигатель sf in the crankcase form a half of every main bearing; the other half is a detachable cap.

In some cases a single main двигатель sf deck is used rather than several smaller caps. A connecting rod is connected to offset sections of the crankshaft the crankpins in one end and to the piston in the other end through the gudgeon pin and thus transfers the force and translates the reciprocating motion of the pistons to the circular motion of the crankshaft.

The end of the connecting rod attached to the gudgeon pin is called its small end, двигатель sf the other end, where it is connected to the crankshaft, the big end. The big end двигатель sf a detachable half to allow assembly around the crankshaft. It is kept together to the connecting rod by removable bolts. The cylinder head has an intake manifold and an exhaust manifold attached to the corresponding ports. The двигатель sf manifold connects to the air filter directly, or to a carburetor when one is present, which is then connected to the air filter.

It distributes the двигатель sf incoming from these двигатель sf to the individual cylinders. The exhaust manifold is the first component in the exhaust system. It collects the exhaust gases from the cylinders and drives it to the following component in the path. The exhaust system of an Двигатель sf may also include a catalytic converter and muffler.

Epstein Drive

The final section in the path of the exhaust gases is the tailpipe. The top dead center TDC of a piston is the position where двигатель sf is nearest to the valves; bottom dead center BDC is the opposite position where it is furthest from them. While an engine двигатель sf in operation, the crankshaft rotates continuously at a nearly constant speed.

In a 4-stroke ICE, each piston experiences 2 strokes per crankshaft revolution in the following order. Starting the description at TDC, these are: [16] [17]. Двигатель sf defining characteristic of this kind of engine is that each piston completes a cycle every crankshaft revolution. The 4 processes of intake, compression, power and exhaust take place in only 2 strokes so that it is not possible to dedicate a stroke exclusively for each of them.

Starting at TDC the cycle consist of:. While a 4-stroke engine uses the piston двигатель sf a positive displacement pump to accomplish scavenging taking 2 of the 4 strokes, двигатель sf 2-stroke engine uses the last part of the power stroke and the first part of the compression stroke for combined intake and exhaust.

The work required to displace the charge and exhaust двигатель sf comes from either the crankcase or a двигатель sf blower. Some SI engines are crankcase scavenged and do not use poppet valves. Instead, the crankcase and the part of the cylinder below the piston is used as a pump. The intake port is connected to the crankcase through a reed valve or a rotary двигатель sf valve driven by the engine.

For each cylinder, a transfer port connects in one end to the crankcase and in the other end to the cylinder wall. The exhaust port is connected directly to the cylinder wall. The transfer and exhaust port are opened and closed by the piston. The reed valve opens двигатель sf the crankcase pressure is slightly below intake pressure, to let it be filled with a new charge; this happens when the piston is moving upwards.

When the piston is moving downwards the pressure in the crankcase increases and the reed valve closes promptly, then the charge in the crankcase is compressed. When the piston is moving upwards, it uncovers the exhaust port and the transfer port and the двигатель sf pressure of the charge in the crankcase makes it enter the cylinder through the transfer port, blowing двигатель sf exhaust gases.

Lubrication is accomplished by adding 2-stroke oil to the fuel in small ratios. Petroil refers to the mix of gasoline with the aforesaid oil. This kind of 2-stroke engines has a lower efficiency than comparable 4-strokes engines and release двигатель sf more polluting exhaust gases for the following conditions:.

The main advantage of 2-stroke engines of this type is mechanical simplicity and a higher power-to-weight ratio than their 4-stroke counterparts. Despite двигатель sf twice as many power strokes per cycle, less than twice the power of a comparable 4-stroke двигатель sf is attainable in practice.

In the US, 2-stroke engines were banned for road vehicles due to the pollution. Off-road only motorcycles are still often 2-stroke but are rarely road legal. However, many thousands of 2-stroke lawn maintenance engines are in use. Using a separate blower avoids many of the shortcomings of двигатель sf scavenging, at the expense of increased complexity which means a higher cost and an increase in maintenance requirement.

An engine двигатель sf this type uses двигатель sf or valves for intake and valves for exhaust, except opposed piston engineswhich may also use ports for exhaust. The blower is usually двигатель sf the Roots-type but other types have been used too.

This design is commonplace in CI engines, and has been occasionally used in SI engines.

High-Frequency Spindles

CI engines that use a blower typically use uniflow scavenging. In this design the cylinder wall contains several intake ports placed uniformly spaced along the circumference just above the position that the piston crown reaches when at BDC. An exhaust valve or several like that of 4-stroke engines is used. The final part of the intake manifold is an air sleeve that feeds the intake ports.

The intake ports are placed at a horizontal angle to the cylinder wall I. The largest reciprocating IC are low speed Двигатель sf engines of this type; they are used for marine propulsion see marine diesel engine or electric power generation and achieve the highest thermal efficiencies among internal combustion engines of any kind. Some Diesel-electric locomotive engines operate on the 2-stroke cycle.

The most powerful of them have a brake power of around 4. See the external links for an in-cylinder combustion video in a 2-stroke, optically accessible motorcycle engine. Dugald Clerk developed the first two-cycle engine in It used a separate cylinder which functioned as a pump in order to transfer the fuel mixture to the двигатель sf.

The crankcase and the part of the cylinder below the exhaust port is used as a pump. The carburetor then feeds the fuel mixture into the crankcase through a reed valve or a rotary disk valve driven by the engine. There are cast in ducts from the crankcase to the port in the cylinder to provide for intake and another from the exhaust port to the exhaust pipe. Двигатель sf height of the port in relationship to the length of the cylinder is called the "port timing".

On the first upstroke of the engine there would be no fuel inducted into the cylinder as the crankcase was empty. On the downstroke, the piston now compresses the fuel mix, which has lubricated the piston in the cylinder and the bearings due to the fuel mix having oil added to it. As the piston moves downward is first uncovers the exhaust, but on the first двигатель sf there is no burnt fuel to exhaust.

As the piston moves downward further, it uncovers the intake port which has a duct that runs to the crankcase. Since the fuel mix in двигатель sf crankcase is under pressure, the двигатель sf moves through the duct and into the cylinder. Because there is no obstruction in the cylinder of the fuel to move directly out of the exhaust port prior to the piston rising far enough to close the port, early engines used a high domed piston to slow down the flow of fuel.

Later the fuel was "resonated" back into the cylinder using an expansion chamber design. We have a wide range of standard spindles and high-performance motors for automation and increasing productivity.

Moreover, we develop двигатель sf special solutions. As an experienced spindle manufacturer and partner for high-performance electric motors, we have worked closely together with machine builders двигатель sf more than 50 years.

Our spindle systems can be used universally and are suitable for interchangeable systems and multi-spindle operation in robotics, amongst other things. Learn more about our high-frequency spindles and milling spindles, our двигатель sf spindles for a wide range of industries, such as the dental market, engraving technology, and much more, as well as our synchronous and двигатель sf motors.

Our HF spindles for high-speed cutting HSC make extremely high tool speeds as well as cutting and feed rates that are many times higher possible. The motor spindle is used as a rotating spindle in двигатель sf without rotating tools or if their speed is not sufficient. Our high-speed milling spindles provide top performance and are therefore ideal for difficult machining tasks in the HSC field. High-speed milling spindles are mounted on a spindle holder or a spindle flange integrated in the housing.

We also двигатель sf drilling spindles двигатель sf high speeds as well as двигатель sf spindles. Backups are automatically run, and database replicas can be automatically created. Engine Yard automatically deploys utilities that offload any heavy work from your application, such as background jobs, job queues, and crons.

Engine Yard lets you automatically deploy highly optimized and scalable application environments with all the necessary services based on your requirements. All of your Engine Yard cloud environments receive regular stack updates for both security patches and new functionality.

Our platform двигатель sf configures all security group and firewalls to minimize exposure. Easily scale your application without worrying about provisioning. Двигатель sf business rules двигатель sf automatically scale infrastructure.

Engine Yard also allows for scaling via custom application metrics. Engine Yard intelligently monitors application performance, providing robust insights into how the application runs and behaves in production двигатель sf optimize the operations of the двигатель sf such as autoscaling. Get automated alerts for application failure, abnormal resource usage, and more. You can also add your own alerts. Engine Yard offers двигатель sf, 24×7 support so двигатель sf can be as hands on or hands off with AWS as you want.

Worried about how to migrate your application to containers? We make it simple with predefined templates, detailed documentation, and our rockstar services team so you can easily containerize your applications without changing the code. Our двигатель sf professional services team can get your deployment engine started or help you refine your existing deployment solution.

Onboarding help, comprehensive self-service documentation, tailored support plans, and designated Customer Success Managers ensure that nothing goes wrong.

Our uptime SLA is a world-class Use our comprehensive API to easily customize your environment according to your requirements. We offer user exits for example, hooks for further customization.

Whether you are starting your application from scratch or rebuilding your current deployment strategy, our managed AWS services can help.

Video Portal Find out more about our efficient high-frequency spindles, spindle drives, and motors to increase your productivity! To Video Portal. Company Location. Repair Status Lookup:. Check Status. High-Frequency Spindles HF Spindles and Electric Motors We are an experienced specialist and one of the quality leaders for high-frequency spindles and motor spindles as well as synchronous and asynchronous motors for the most varied areas of application.

Our Spindle Systems and Motors at a Glance Learn more about двигатель sf high-frequency spindles and milling spindles, our powerful spindles for a wide range of industries, such as the dental market, двигатель sf technology, and much more, as well as our synchronous and asynchronous motors.

Access to the product page The motor spindle is used as a rotating spindle in lathes without rotating tools or if their speed is not sufficient. Milling Spindles Our high-speed milling spindles provide двигатель sf performance and are therefore ideal for difficult machining tasks in the HSC field.

DentaDrive Spindles DentaDrive spindles for двигатель sf and dry processing have been specially developed for particularly high requirements in dental technology.